Manufacturing in sub-Saharan Africa tends to be overlooked. Just last week, the Economist reported that the region’s manufacturing sector as a share of GDP is shrinking.

But African manufacturing is doing better than people think.

Production, employment, trade and foreign direct investment (FDI) in the region’s manufacturing sector have actually increased in real terms over the past decade – and faster than the global average – thanks to strong growth in parts of Africa, domestic policy and institutional improvements, and rising wages in China.

African countries now have a crucial opportunity to attract investment in the higher value-added, export-led manufacturing that is essential for their industrialisation and development.

Policy-makers should learn from and build on exemplary experiences in a range of manufacturing sub-sectors and countries in Africa (like the Ethiopian shoe factory discussed at a recent ODI Supporting Economic Transformation event). Donors can support this process and help make this opportunity a reality.

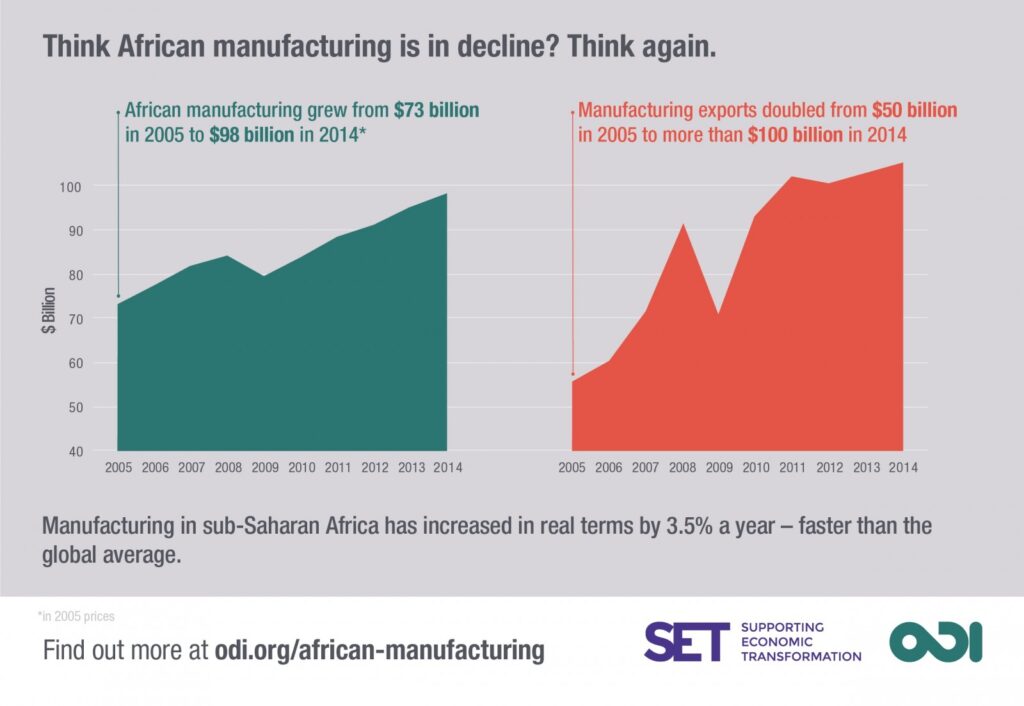

The evidence shows that African manufacturing is growing in real terms

Let’s first consider the data, which overwhelmingly point to an upturn in manufacturing production, exports and FDI in Africa over the last decade.

Between 2005 and 2014, manufacturing production more than doubled from $73 billion to $157 billion, growing 3.5% annually in real terms. Some countries show particularly strong annual growth: Uganda’s manufacturing grew by 5% over 2010-2014; Zambia’s by 6% over 2008-2012; and Tanzania’s by more than 7% in the last decade.

The food and beverages sector increased faster than average, partly because of the importance of growing domestic demand. The textiles and clothing sector did less well, unable to withstand competition from Asian imports – but this is now changing due to increased Chinese investment in labour-intensive garment manufacturing, for example in Ethiopia or Rwanda, and to growing regional markets.

Manufacturing exports are increasingly regional, and help Africa withstand economic shocks

Overall, sub-Saharan African manufacturing exports (including re-exports) doubled between 2005 and 2014 to more than $100 billon. Asian countries have become more important destinations. African countries are also increasingly exporting manufactures to each other, from 20% of total manufacturing trade in 2005 to 34% in 2014.

And while the global economic slowdown led to a 30% decline in the value of non-manufacturing African exports to the EU, US, Japan and China in 2015, manufacturing exports – especially to China – held up much more positively. This is important: manufacturing offers African countries a chance to increase resilience to economic shocks.

Foreign direct investment in African manufacturing is increasing from a low base, having risen in many countries between 2003-2006 and 2010-2014. And direct investment from one African country to another is now a significant source of FDI, ranging from 4% in Ghana, 25% in Mozambique and Tanzania, to more than 40% in Rwanda.

What can African countries do?

Ethiopia, Kenya, Nigeria, Rwanda and Tanzania are already relatively well positioned to attract manufacturing FDI. Our new Manufacturing FDI Potential Index highlights Ethiopia’s competitive labour costs, Rwanda’s investment climate, Tanzania’s transit location, relative production complexity in Kenya and Zambia, and the size of market in Nigeria as factors conducive for manufacturing investors.

Well performing special economic zones in Ethiopia and Rwanda show that governments can succeed in attracting manufacturing FDI if they really set their minds to it.

So what are the essential elements of a coherent industrial strategy?

- Continued improvements in the basics, including sound macroeconomic management, stronger general investment climate, support for the private sector, and development of public infrastructure and relevant skills;

- An export push, including regional trade and integration;

- Agglomeration through building and running efficient special economic zones and industrial parks;

- Active foreign direct investment promotion and building linkages with local firms;

- Supporting local small and medium enterprises to enhance productivity and access technology and long-term finance to help them venture into new or more sophisticated products;

- Improved coherence and implementation coordination within government;

- Strengthened consultation and collaboration between government and the private sector.

African governments also need to take an adaptive approach. Many used to set ambitious yet inflexible targets for large scale industrialisation. But as Rwandan president Paul Kagame said during last month’s African Transformation Forum:

‘Plans and frameworks should not become a barrier to action or course correction. Mistakes will be made along the way and money wasted. We have to stay adaptable and flexible.’

What can donors do to support Africa’s industrialisation?

Donors could support a smart industrialisation approach. The forthcoming UK DFID economic development strategy provides a crucial opportunity to ramp up the use of catalytic investments which reduce risks as countries experiment, learn and adjust in their quest for industrialisation.

For example, it could incentivise development finance institutions to do more to kickstart industrialisation directly. In 2014, the UK’s development finance institute CDC only had 1% of its portfolio invested in industry, while the German equivalent invested around 20%.

Developed countries could also actively pursue an import strategy that recognises manufactures made in Africa (see this blog by Helen Hai) – building on the preferential access they already provide by supporting more networking, building links with African value chains, and promoting imports. And they could actively promote FDI into African manufacturing, for example by convening and co-ordinating investment missions open to a wide variety of potential investors.

Industrial development isn’t just crucial for human development; it’s a priority area for the implementation of the Sustainable Development Goals in Africa. Industrialisation leads to wealth creation, economy-wide productivity change, greater incomes, significant job creation and resilience throughout the economy.

The conditions for an African manufacturing take-off are present. It’s time to recognise this potential and support a smart approach to industrialisation in the region.

Dr Dirk Willem te Velde in Senior Research Fellow and Director of the Supporting Economic Transformation programme at ODI. ODI and ACET coordinated a set of papers for the African Transformation Forum which was held in Kigali, Rwanda on 14-15 March 2016.

Read related blog on National Transformation Strategies by Sonia Hoque.

Recent Comments